Architecture & Construction Tape

The Tape Lab provides adhesive tapes and flexible materials that are used in both interior and exterior architecture, construction, and the commercial building industries. We specializes in creating custom adhesive tapes for the architecture and construction industry by die cutting, sheeting and slitting custom widths.

The Tape Lab’s team of application engineers has a wealth of knowledge and experience in the architecture and construction tape converting industry, so we can help customize your adhesives and materials to meet your unique specifications.

The Tape Lab partners with the leaders in the construction industry with a comprehensive line of tapes and adhesives, such as 3M™ VHB™ tapes, strong enough to replace rivets and screws while remaining virtually invisible.

What We Offer

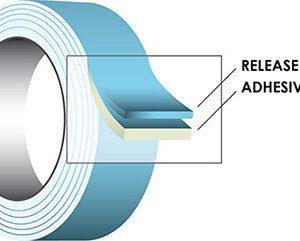

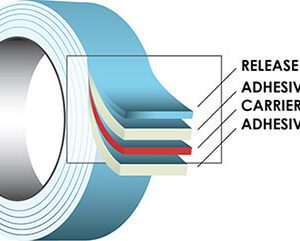

We customize mirror tape for transporting mirrors, as well as installing them in hard to bond to surfaces. These tapes are double coated foam tapes that come in a variety of thicknesses. We also offer masking tapes that offer protection for a wide range of surfaces, from stucco to paper to metal. We also offer specialty tapes, including indoor/outdoor carpet seaming tape and protection tapes and films that withstand harsh environmental conditions.

Architecture & Construction Applications

The Tape lab applications include glazing tape, sealing tape and gasketing tapes. Our engineers slit rolls of bonding and mounting tapes for installing windows and doors as well as decorative trims.

We manufacture solutions for affixing signage on commercial buildings and customize tape solutions for both interior signage as well as exterior signage. Our tapes can stick to the toughest surfaces in the building and construction markets.

Architecture & Construction Capabilities

We produce slit rolls of foam tape that is AMA approved for the fenestration market. The Tape Lab can make your life a lot simpler when you partner with us as your converter. We can slit, die cut and package all of your materials in our state of the art manufacturing facility and offer custom multi-layer laminations, die cuts with extended liners or butterfly tabbed liners (like a bandaid), island placement and registration of materials, printed logo liners, short roll winding and rewinding. We also offer design assistance, prototyping, and basic testing all the way through full scale production.